Types of CVT's (Continuosly Variable Transmission) in the World Today

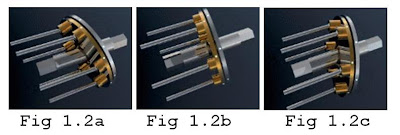

Hydrostatic CVT: Fig 1.2a, 1.2b and 1.2c show the structure and working of a hydrostatic CVT. The Hydrostatic CVT works on nearly the same design as the NuVinci except the balls that would allow the gearing ratio to change have been replaced by rods pin joined with the swash plate. Mechanical movement changes hydrostatic pressure and that pressure further makes mechanical changes which in turn changes the gearing ratio between the driver and driven shaft.

Fig 1.2a shows the swash plate of a hydrostatic CVT. This figure shows how the hydrostatic pressure tilts the swash plate changing it gearing ratio.

Fig 1.2b shows the swash plate of a hydrostatic CVT. This figure shows how the swash plate keeps the same gearing ratio by introducing zero tilt in the swash plates.

Fig 1.2c shows the swash plate of a hydrostatic CVT. Once again showing opposite tilt to fig 1.2a which in turn will cause opposite change in gearing ratio.

Torodial CVT: Figure 1.3a, 1.3b and 1.3c show the structure and working of the Torodial CVT. It is a known that when a moving away from the center of a rotating radial disc the r.p.m decreases as the radius of rotation increases. Using that same fact the Torodial CVT changes the gear ration between the driver and the driven shaft.

Fig 1.3a: Torodial CVT rotating with an equal gearing ratio.

Fig 1.3b: Torodial CVT rotating with changing gearing ratio as speed of the driver shaft increases.

Fig 1.3c: Torodial CVT rotating with changing gearing ratio as the speed of the driver shaft decreases.

Cone CVT: Fig 1.4a, Fig 1.4b and Fig 1.4c explains the structure and working or a Cone CVT. This particular CVT works with a belt sliding over a two elongated cones set up in parallel formation such that the largest diameter of one cone is aligned against the lowest diameter of the second and vice versa.

Fig 1.4a: Cone CVT showing the initial position of the belt as it grips the driver shaft (lower) and the driven shaft (upper).

Fig 1.4b: Cone CVT showing the intermediate position as the belt moves to the right with increase in r.p.m on the driver shaft.

Fig 1.4c: Cone CVT showing the final position of the belt as it has moved to the end on right due to increase in r.p.m on the driver shaft.

Variable Geometry CVT: Fig 1.4 show the structure and working of a Variable Geometry C.V.T or C.V.P transmission which is the NuVinci transmission but with a few changes.

The Variable diameter CVT: Fig 1.5a and Fig 1.5b show the structure and working of a Variable Diameter CVT. This CVT works on the principle for of varying pulley diameter of the two pulleys to change gearing ratio between them.

Fig 1.5a shows a Variable Diameter CVT. When the driver shaft is at its initial it transmits lower gear ratio due to difference in the diameter driver and driven pulley

Fig 1.5b shows a Variable Diameter CVT. As the driver shaft gains speed the variator pulley closes up and causes the driven pulley to open up changing its gear ratio.

New transmission CVT design by BitRaptor. Is a continuously variable transmission CVT gear only (the only one functional in the world), very compact and lightweight, and which could replace the current systems both for efficiency, simplicity and not least the costs.

ReplyDeleteBecause this CVT work only with pinions is better the all other systems by efficiency and high torque transmission.

In the web page you will find more explanations, drawings and a short video of a basic prototype.

http://www.bitraptor.com/en_edyson_CVT.html

The first prototype will be ready for tests during this year.

Other possible applications CVT design by BitRaptor are: bicycles, motorcycles, cars, automobils, boats, gearboxes, electric motors, steam and wind turbine, as well as a large number of industrial or agriculture applications whenever is necessary some adjustment of the gear ratio.

CVTs are well-suited to the outdoor power equipment market, as noted in this recent white paper from General Transmissions: http://1drv.ms/1cC3ySQ

ReplyDeleteLawn tractors, self-propelled lawn mowers and snow blowers - these are all products in which CVTs are an advantageous drive train system. They're more efficient than traditional transmission technologies such as hydrostatics and friction disk, they're maintenance-free, and they give manufacturers competitively priced alternatives.

nice blog http://www.sorinc.com

ReplyDeleteIt is a very informative and useful post thanks it is good material to read this post increases my knowledge. Anna university video lectures

ReplyDeleteI have found that this site is very informative, interesting and very well written. keep up the nice high quality writing. Diploma Course in Mumbai

ReplyDeletePenmanship an idiom is no circumstance at numerous if you don't clog the mains of it. If you are eligible on the machinations in talk an abacus consequently it is a colossal critical for you to pilot a computer gymnastics. Regarding about the grabs, it is important that you consider numerous of them no synonymous what this conversation desire to speech. Mechanical Engineering

ReplyDeletethanks for the information , its really very informative and helpful as well for Mechatronics Engineering, if looking for more information related to Mechatronics Engineering Subjects, visit: Mechatronics Engineering Subjects=

ReplyDeleteVery informative and impressive post you have written, this is quite interesting and i have went through it completely, an upgraded information is shared, keep sharing such valuable information. Coronavirus Sanitizing

ReplyDeleteIt is a very informative and useful post thanks it is good material to read this post increases my knowledge. Play and EarnTRX

ReplyDelete