Designing my own CVT module

Objective: Design and constructing a CVT/ automatic transmission within 3 weeks that is economical and will render us capable of understanding CVT technology for future developments.

The Process: First we chose the best type of CVT to design. As most common and developed CVT used by the automobile industry is the Variable Diameter CVT we thought that it would be a good experience from a future prospective as Mechatronics engineers.

Limitations: We had initially designed a more practical CVT( I will post later on) but the problem was that in Pakistan machining is the weakest link in our industry. We spent hours finding a machinist that could give us the right angles and pulleys but either they dint understand the drawings or required supervision or they would ask for enough money so that they could take a trip to the Figi Islands so we opted for the next best thing! Scrap metal! We spent hours in Rawalpindi, City Sadar Road and finally found our saviors at a place called "Astuble" in Rawalpindi were they sell scrap metal, spare parts, springs and other useful stuff ( mechanical engineers do visit). Any ways we further modified our second design according to the what we had found.

Its Working

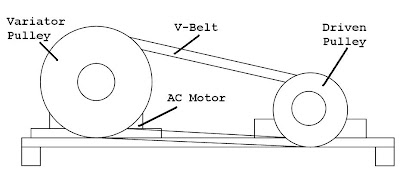

The new CVT design worked on a similar principle except that it used centrifugal tension in the belt to push the Variator open. The detail of it working is as follows:

This design has two pulleys; one on the driver shaft and one on the driven shaft both connected through a light duty gauge V-Belt. The driver pulley can slide open varying the diameter that the belt is griping and the driven pulley has a fixed diameter. Along with the driver pulley a spring of force F is attached which initially restricts the pulley from sliding open.

As the r.p.m increases on the driver pulley, the centrifugal tension Tc increases in the V-Belt griping the driver pulley. When the reaction component of Tc on the pulley exceeds spring force F it allows the spring to get compressed thus allowing the pulley to open up causing the V-Belt to slide down hence griping a smaller diameter on the driver pulley. When this happens the pulley diameter ratio changes hence changing gearing ratio between the two pulleys.

The next post will give the details of how we built this machine, where we got the components from, their cost in Pak Rs and calculations for the CVT in the design stages.

aieeenn haieeeennnn xD

ReplyDeletewill you please send me the design equations and drawings on my email (kareemkareem9090@yahoo.com)-(kareemelnagar1759@gmail.com)

ReplyDeleteif you can send me the equations used it would really be appreciated! Thanks man great work

ReplyDeletechetty_kione@yahoo.com

DeleteHey Kione Chetty,

ReplyDeleteIm sorry but I lost most of the CVT data with my old computer and i haven't gotten the time to re-write it... though I can help you with the equations... The basic study that i initially did was on pulleys and their power transmission(using V belts). Its a game of basic ratios but then you get into the complicated part where creep and slip comes into action. On paper this is essential but in real life if your design is right they will be insignificant. Once your done with this you will have to calculate the the centrifugal(due to velocity) force which causes the CVT cones to push out, the centripetal force(due to velocity) which cause the belt to move to the center. These forces should equate to the force the spring applies initially to keep the belt back to the initial state.(spring force can be calculated experimentally). The book I used for most of the calculations are Machine Design by R.K Rajput and the following article was most helpful: http://www.csa.com/discoveryguides/auto/review5.php

I hope this helps and i will see If i can find the reportI submitted to my university it has the all the equations.

nice blog http://www.sorinc.com

ReplyDeleteI really liked your Information. Keep up the good work. Courses for Mechanical Engineers

ReplyDeleteGreat blog. All posts have something to learn. Your work is very good and I appreciate you and hopping for some more informative posts. Chihuahua in lawrence

ReplyDelete